This is AI generated summarization, which may have errors. For context, always refer to the full article.

Did you know that Wimbledon tennis balls are made in Bataan? And that they travel over 50,000 miles before they even reach the court?

MANILA, Philippines – While some would find it hard to appreciate products made in the Philippines, one might be surprised to know that tennis balls used at Wimbledon, the world’s oldest and most prestigious tennis tournament, is in fact made in Bataan, Philippines.

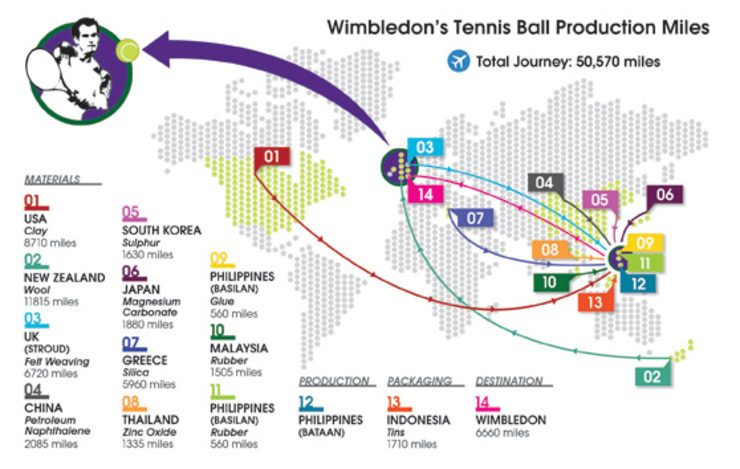

The tennis balls, according to a study by the University of Warwick Business School (WBS), travel a total of 50,570 miles, spanning 11 countries and 4 continents before they are manufactured in Bataan then packaged in Indonesia and eventually flown to Wimbledon in London, England, for one of the 4 Grand Slam tournaments.

Dr. Mark Johnson, Associate Professor of Operations Management at Warwick Business School, traced back the intricate supply chain of Slazenger’s official Wimbledon ball, pinpointing exactly where the ball’s materials come from, as detailed by the WBS graphic below.

“It is one of the longest journeys I have seen for a product,” Dr. Johnson said.

“On the face of it, travelling more than 50,000 miles to make a tennis ball does seem fairly ludicrous, but it just shows the global nature of production these days, and in the end, this will be the most cost-effective way of making tennis balls.”

The graphic shows how various materials such as clay and wool come from the US and New Zealand, respectively. The Philippines also supplies glue and rubber from Basilan.

The process involves putting the ball on a journey of collecting the materials it needs close to its primary sources.

“A complex supply chain sees clay shipped from South Carolina in the USA, silica from Greece, magnesium carbonate from Japan, zinc oxide from Thailand, sulphur from South Korea and rubber from Malaysia to Bataan (in central Philippines) where the rubber is vulcanized – a chemical process for making the rubber more durable,” the study said.

“Wool then travels from New Zealand to Stroud in Gloucestershire, where it is turned into felt and then sent back to Bataan in the Philippines.

“Meanwhile, petroleum naphthalene from Zibo in China and glue from Basilan in the Philippines are brought to Bataan where Slazenger, which was bought by Sports Direct in 2004, manufactures the ball. Finally tins are shipped in from Indonesia and once the balls have been packaged they are sent to Wimbledon.”

Johnson further explained how the entire process is centered around the Philippines, where the manufacturing labor is at a “very low cost.”

“Slazenger shut down the factory in Barnsley in the early 2000s and moved the equipment to Bataan in the Philippines,” he explained.

“They still get the felt from Stroud, as it requires a bit more technical expertise. Shipping wool from New Zealand to Stroud and then sending the felt back to the Philippines adds a lot of miles, but they obviously want to use the best wool for the Wimbledon balls.

“Apart from that part, they have managed to keep the supply chain relatively short, and centred round the Philippines.”

Slazenger, a well-known British sports equipment manufacturer, has supplied tennis balls for Wimbledon since 1902. – Rappler.com

There are no comments yet. Add your comment to start the conversation.