SUMMARY

This is AI generated summarization, which may have errors. For context, always refer to the full article.

MANILA, Philippines – Samsung revealed the cause of the Note7 explosions on Monday, January 23, ultimately confirming the consensus among observers: the batteries were faulty.

Describing its investigations as thorough and comprehensive, the Korean brand ruled out every other possible cause of the incident such as the phone’s software, wireless charging tech, or iris scanner.

To ensure objectivity, Samsung said it commissioned 3 expert organizations to help with the investigation: “safety science” company UL, US-based components-testing facility Exponent, and Germany-based TUV Rheinland, which assessed factory and logistical factors.

Their findings, as Samsung noted in its presentation, could help the whole industry come up with safer batteries and products in the future.

Manufacturing defects

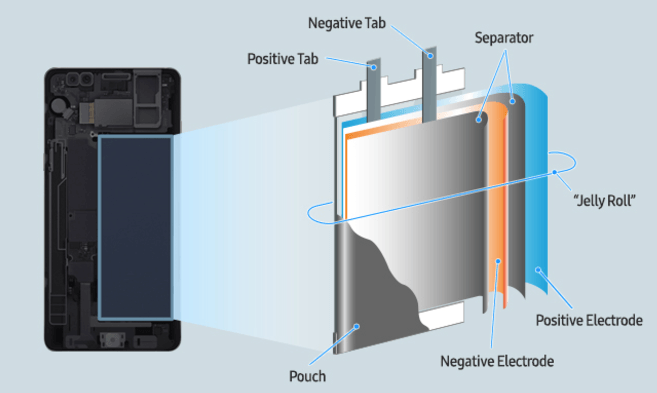

UL – analyzing batteries which exploded and new ones provided by Samsung – concluded that flaws in the battery design and manufacturing caused the explosions.

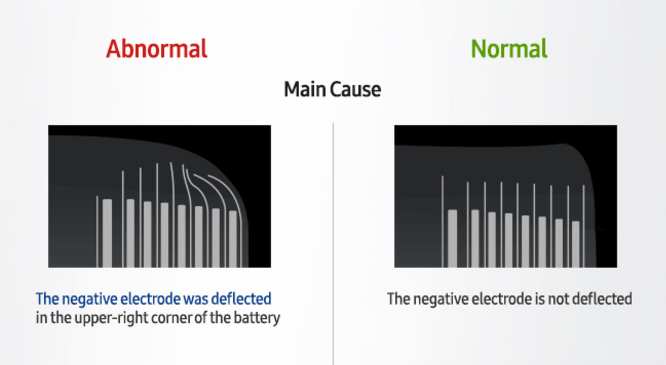

In the upper corners of the battery (the side where the negative electrodes are located), deformations were found. The separator between the positive and negative ions were found to be too thin, which led to poorer protection against short circuiting. The high-energy density found in Note7 batteries was also a contributing factor, making matters worse and causing more severe explosions.

Another organization, Exponent, saw the deformations in the upper corner of the battery too, and noted that these caused “thermal failure” even with normal use. Another design flaw it found was that the cell’s pouch “provided inadequate volume to accommodate the electrode assembly.” Simply put, the pouch containing the battery cells had been too small.

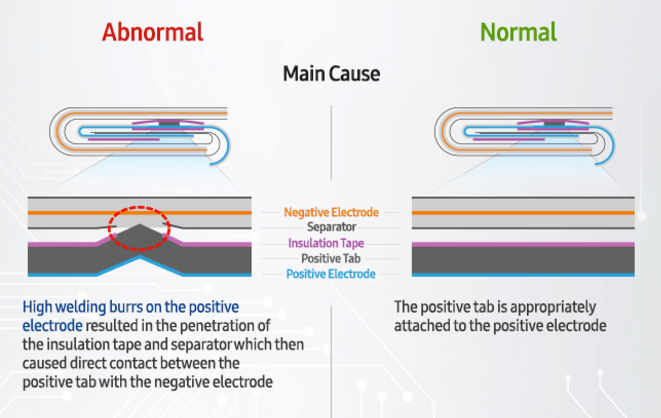

In the second batch of Note7 units – the ones that were supposedly fixed and therefore safer – UL saw evidence of poor production quality along with battery design issues found in the first batch. The experts found that insulation tape was missing in some units, enhancing the chance of a short circuit. The welding points protruded in some cases, causing it to puncture other battery elements. Some parts also showed misalignment, which heightened the chance of an explosion as well.

Exponent reaffirmed these findings for the second batch, and identified welding defects and inconsistencies in the placement of the insulation tape as the cause of the incidents.

Logistical aspects

TUV Rheinland – a company that issues certifications to electronic and automotive manufacturers worldwide based on the standards of the International Electrical Commission – took a look at the factories and logistics involved in the making of the Note7 batteries.

They looked into the assembly of the phones in the factories and potential safety issues caused by transportation of the batteries.

Inspecting two Samsung factories – one in Vietnam and one in Korea – the organization found no issues regarding the touching, handling, and storage of the batteries that would have affected the integrity of the batteries.

Batteries were also put under a transport test, in which the units were subjected to stressful transporting conditions from the factory in Hanoi, Vietnam to the drop-off point in Dongguan, China. The batteries showed no significant changes after the tests. – Rappler.com

Add a comment

How does this make you feel?

There are no comments yet. Add your comment to start the conversation.